Posted: October 4, 2019

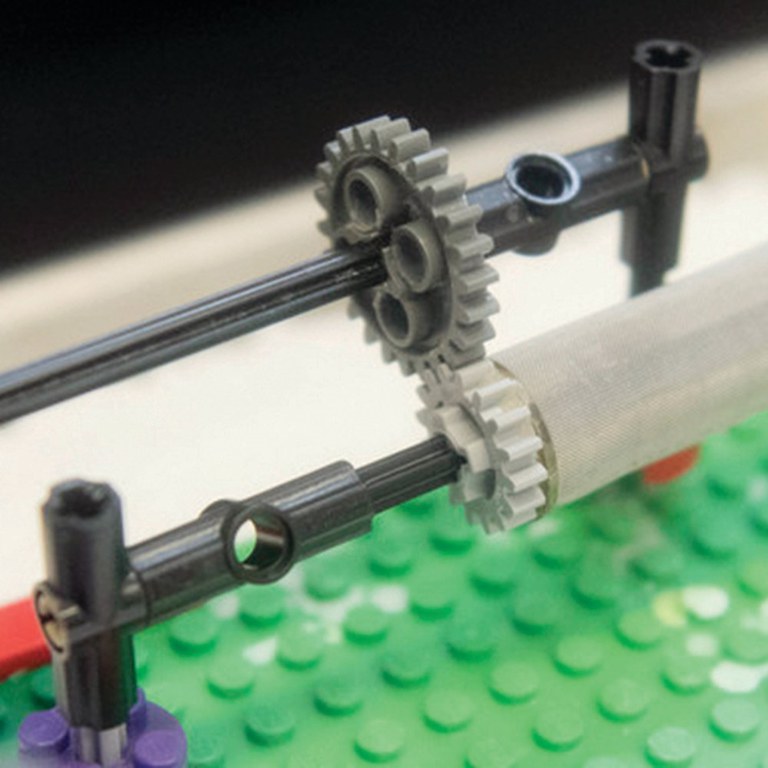

Researchers build starch backbones for lab-grown meat using LEGO pieces.

The creative possibilities for building with LEGOs are seemingly endless. Now researchers have found a new use for the toy bricks. Gregory Ziegler, professor of food science, and colleagues have created a technique to spin starch fibers using LEGO pieces that could have future applications for lab-grown "clean" meat.

To culture meat, animal muscle cells are cultivated in a nutrient-rich broth. If no structural support is provided, the cells grow without organization and resemble ground beef. It is more challenging to grow a steak-like product because the muscle cells must grow on a scaffold of appropriate size and alignment to form the characteristic texture consumers expect of a filet mignon or T-bone.

The team wanted to create a starch scaffold for cultured meat because starch is edible and clean, and is also among the least expensive natural fibers out there.

"The reason we chose LEGOs is because of the water and ethanol in there; we didn't want the device to be conductive," said Ziegler. "The plastic was perfect."

According to Ziegler, no one had been able to electrospin pure starch fibers before. The team figured out a way to do it using a wet electrospinning technique.

To produce fine starch fibers using electrospinning, electricity is applied to a starch solution as it dispenses from a nozzle. The electrical field that forms between the nozzle and a rotating collection drum draws the starch into long threads. In their wet electrospinning method, the team submerged the drum in a bath of alcohol and water to help congeal the fibers.

By altering the drum rotation speed and the amount of ethanol in the electrospinning bath, the researchers optimized fiber alignment in the starch mats. They also found that mats with better aligned fibers were stronger than those with a crisscrossed array.

Ziegler says the next step is to test if muscle cells will grow on the starch mats and whether they develop in alignment with the fibers. The researchers also are exploring ways to make starch fibers in specific patterns using 3D-printing technology. In addition, they plan to scale up their equipment to produce larger quantities of the fibers.

--Asher Jones

Features

Fostering Forests

Across the United States, forests face unprecedented threats, and scientists in Penn State's College of Agricultural Sciences are conducting novel and complex research to conserve them.

Buzzing With Purpose

Community scientists work to protect Pennsylvania's wild bees

Conservation Reimagined

Exploring new approaches to cope with a changing climate